ASM Mechanical Company

152 Watchogue Rd, Staten Island, NY 10314

Contact: Paul Stessler

Phone: (347) 692-4777

Fax: (718) 698-6361

Website: http://asmhvacnyc.com/

Profile

ASM Mechanical Company is a licensed and insured mechanical contractor located in Staten Island, NY. We service all of the 5 boroughs of NYC and most of middle to northern New Jersey.

Services

We are a full-service mechanical contractor. We specialize in heating, ventilation, air conditioning and commercial refrigeration. We are also boiler specialists for hot-water and steam heating systems. We also specialize in radiant heating and snowmelting systems.

Gallery

Case Study

Trane Vapor Vacuum system in the historical district of Perth Amboy New Jersey

Challenge

Restoration of a Trane vapor vacuum 2 pipe gravity return system. Carefully bringing the system back to its original functionality while preserving it's historical integrity. Customer complained of extremely high fuel bills, uneven heating and very loud water hammer during the middle to the end of the cycle.

Approach

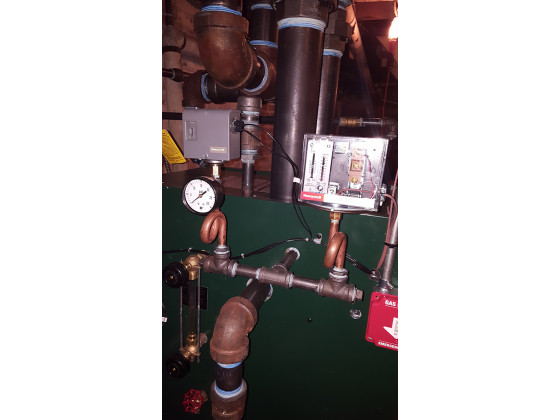

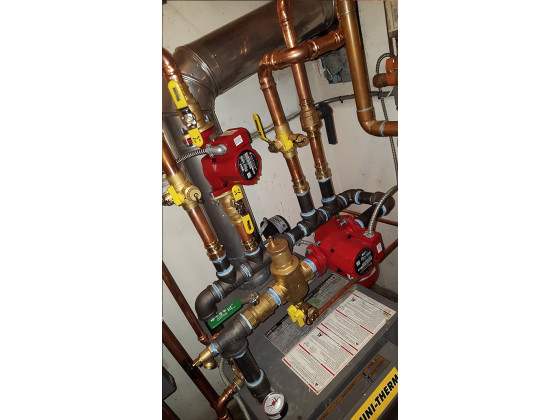

During our initial walkthrough, we discovered that the system still had its original steam traps from 1922. Many of the traps were malfunctioning and some had been entirely removed. The system pressure was improperly set at 8 PSI, far too high for any vapor sytem and most 2 pipe gravity return systems. Additionally, the steam main air vents and return air vents were equipped with the original vacuum air vents designed for coal-burning systems from the early 20th century. We also found the thermostat incorrectly configured for warm air heating, further contributing to the system's inefficiency.

Solution

We removed all radiator trap covers and bellows, installing new trap covers and cage units, and properly pitched and supported all system piping. We also replaced the steam main and return line air vents, implementing a "master venting" strategy for the mains and returns to mimic an "open pipe". To ensure precise low-pressure operation, we replaced the existing pressuretrol with a vintage mercury vaporstat, calibrated to cut out at 8 ounces of pressure. The mercury vaporstat was selected due to the inability of newer micro-switch vaporstats to function effectively at such low pressures. Additionally, we performed a thorough maintenance on the boiler, treated the boiler water, and replaced the thermostat, setting it specifically for steam operation. Upon starting the system, the customer was amazed at how quickly the steam circulated and heated all radiators evenly. The water hammer issue was completely resolved, and the customer reported nearly a 50% reduction in fuel costs. As we always remind our technicians: "If you can do what others say is impossible, people will find you." – Dan Holohan