This all-technical, three-hour seminar will make you familiar with the many types of old steam heating systems and what goes wrong with them. Dan Holohan’s easy-to-follow...

Can You Lift Condensate?

Inside the vessel, the steam surrenders its heat and reverts to condensate or water. The condensate has to be returned to the boiler feed unit and boiler. If the condensate return pipe is at a lower elevation than the steam trap discharge, then it is easy to connect the two. What happens when the condensate pipe is above the steam trap elevation? There are a couple of options for doing that. One option is to use your telekinetic power to lift the condensate as Yoda can do in Star Wars. If you are a mortal like me, we are limited to two other options.

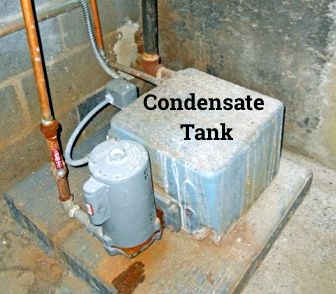

The first alternative is to install a condensate return tank on the floor close to your vessel. You pipe the steam trap discharge to the tank, and the pump on the tank will transport the condensate back to the boiler feed unit where it will be ready for the next call for water by the boiler. This is my preference as it works well. There are a couple of drawbacks to this choice. The first is the cost of the condensate tank which will range from one to three thousand dollars. The second consideration is the maintenance of this pump. It will require maintenance and the life expectancy is about 15 years.

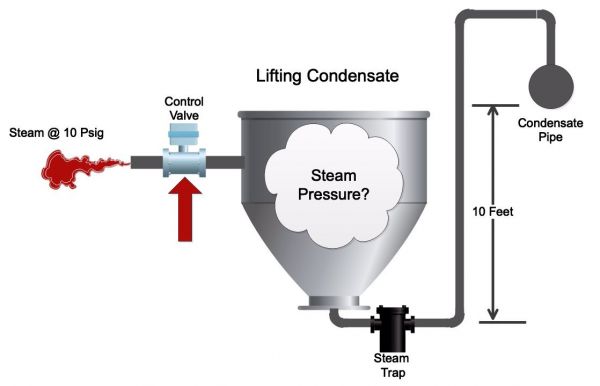

The second alternative to returning condensate to a pipe at a higher level is to use the steam trap to lift the condensate. This is almost as good as telekinesis. If you remember from high school physics, one pound of pressure will raise water 2.33 feet. Let us assume the condensate pipe is ten feet above the steam trap discharge. If you divide ten feet by 2.33, we would need 4.3 pounds of steam pressure. No problem, you think as your boiler is set for ten psig. That ten-foot measure is only to the bottom of the pipe. You never want to pipe the condensate or steam takeoffs into the bottom of the steam pipe. All the condensate that is traveling inside the horizontal steam pipe would come falling into the pipe. It would fill the pipe quickly, and your vessel would stop heating. Oh yeah, it would sound like you are at a Blue Man Group concert with all the banging of the pipes. So, you would add two more feet to the calculation to raise the pipe discharge to the top of the horizontal pipe. We would need a little over 5 pounds of pressure to lift the condensate up and into the condensate pipe. We are running ten pounds of pressure you think but are you? Does the Mash Tun have a modulating valve on the steam pipe supplying the vessel? If so, you only have ten pounds of pressure when the valve is wide open. The other consideration is what happens when you are done, and the boiler is off. The column of water could stay there until the next brewing cycle, and the banging could start.

You can see why I would rather use a condensate tank and pump.

Would you like to learn more from Ray Wohlfarth? Check out his seminars, books, and blog about brewing with steam.

Leave a comment

Related Posts

We always have turkey for Thanksgiving. I mean who doesn’t? My job wasn’t to cook it, though; it was to eat it.

I had written a story for Plumbing & Mechanical a while back about a fella in Canada who sent me this email: "Our problem is that five out of hundreds of univentilator co...