In this presentation, Gary Klein shares important information about air source heat pump water heaters (HPWH), with particular attention paid to where the warm air comes ...

Indirect Hot-Water Heating Q&A

Q: What's "indirect" heating?

A: It's a method of heating the old-timers used to warm fresh air before it entered a building.

Q: How did they do this?

A: They placed the indirect radiators outside the room they were heating (that's where the name "indirect" comes from). They used ductwork to direct the fresh, outside air across these remote radiators where it would be warmed before rising into the rooms.

Q: Where exactly did they place these radiators?

A: Almost always in the basement, and usually right under the room they were heating, but they could also put them in a central location and feed the ductwork off to the rooms. It all depended on the size and shape of the house.

Q: What sort of houses had this type of heating system?

A: Big houses! Indirect heating was mostly the province of rich folks. Rich folks loved this type of heating system.

Q: How come?

A: At the Turn of the Century, many people believed stale air (they called it "vitiated air") was a prime cause of disease. Those who could afford it heated their homes with a constant supply of warmed, fresh air. They thought this was the healthiest heating system possible.

Q: Were they right?

A: Since this was the first residential, central heating system to combine heating with ventilation, they were certainly on the right track. Indirect hot-water heating was an improvement over the direct hot-water and steam systems of the time, and as far as health goes, it was a great improvement over the stoves most people used.

Q: Were these systems expensive to operate?

A: There sure were! That's why you'll find them mostly in the homes of long-gone wealthy folks.

Q: What does an indirect radiator look like?

A: Most look like small cast-iron sectional boilers, without the jacket, of course.

The old-timers used iron rods to suspend them from the basement ceiling inside the duct. Many are heavy enough to cause the floor above to sag. The first time you run across one can be a pretty intimidating experience.

Q: Were all the radiators made from cast-iron?

A: No, some were steel, and these looked a lot like fin-tube radiation, minus the enclosure.

A typical steel, indirect radiator could have a dozen or more tubes set up side by side within the duct. Air flowed by gravity from the outside to the rooms.

Q: Did they heat the entire house with these?

A: Sometimes they did, but most often they used a combination of indirect radiators and direct radiators. Direct radiators are the "regular" ones which sit in the room and heat the same air over and over again.

Q: How did they decide where to put the direct radiators and the indirect radiators?

A: The large rooms on the first floor were almost always heated with indirect radiators, as were the bedrooms on the second floor (they worried about vitiated air getting them as they slept!). If the house had a third floor, it was usually heated with direct radiation since these rooms were typically not used every day. The servants' quarters were always heated with direct radiation.

Q: Were there any radiators which heated both directly and indirectly.

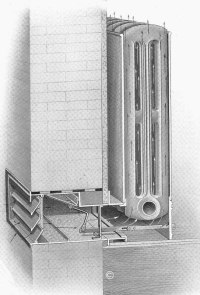

A: Yes. These were "regular" radiators which the old-timers set over an outside air duct. Here's what one looks like.

They did a nice job of mixing and warming fresh air from the outdoors with the air that was already in the room.

Q: Did these direct/indirect radiators heat by convection?

A: Yes, they did. Whenever you place a radiator directly in the room you'll get convection currents. The heated air will rise off the radiator as the cooler air scoots across the floor.

Q: Did indirect systems promote convection air currents in the room?

A: Not to the same extent because the heat source was the floor or wall register. Return air had no way of flowing into a cooler place.

Q: So where did the return air go?

A: It left the house through cracks around the windows and doors.

Q: How can you tell the potential Btu output of a cast-iron indirect radiator?

A: First, you have to be able to see the radiator well enough to count and measure its sections. The duct will have an access door, but it's sometimes difficult to get a clear view of the radiator.

Q: Let's say I can get the measurements I need. Where do I find the ratings?

A: The American Radiator Company was once the largest manufacturer of indirect radiation. The unit you have is probably one of their "Vento," "Perfection Pin" or "Sanitary School Pin" models. Their 1925 book, The Ideal Fitter book, which you'll find in our Heating Museum, shows the ratings for these.

Q: What is a Square Foot of Equivalent Direct Radiation equal to in Btu/hr?

A: For indirect radiators, we can safely say that each square foot of EDR will be equal to 150 Btu/hr when the average water temperature is 170 degrees F

Q: Okay, now suppose I can't see the radiator at all?

A: As I said, there's almost always an access door in the ductwork, but if worse comes to worse, you can estimate the size of the indirect radiator by checking the size of the hot water tapping feeding it. Here's a rule of thumb for you:

- A 1-1/4" tapping can feed up to 60 square feet of indirect radiation.

- A 1-1/2" tapping can feed up to 90 square feet of indirect radiation.

- A 2" tapping can feed up to 100 square feet of indirect radiation.

Q: Can I check the size of the radiator by measuring the size of the hot air flue connected to it?

A: You can get a fairly good idea. The old-timers based the size of the hot air flue on the square foot of connected indirect radiation that it contained. For hot water jobs, they allowed two square inches of flue per square foot of radiation. If you have absolutely nothing else to go by, figure the square inches of the hot air flue (by multiplying its two sides together) and then divide that by 2. That will give you a good estimate of the square feet of radiation inside that duct.

Q: How about the cold-air inlet flue, what size will that be?

A: Usually, it's between 2/3 and 3/4 the size of the hot-air flue.

Q: Why is the cold air flue smaller than the hot air flue?

A: Because hot air takes up more space than cold air.

Q: Does it matter where the old-timer set the radiator inside the duct?

A: Yes, an indirect radiator should be a about 10 inches below the top, and at least eight inches above the bottom of the flue. It should also be tight against the sidewalls of the duct. Just like this.

Q: Are these dimensions crucial?

A: They are if you want to get the proper flow of air across the radiator.

Q: But isn't this something the old-timers took care of years ago? Why should I have to worry about it now?

A: The old-timer did take care of it many years ago. But suppose that cast-iron indirect radiator you're staring at decides to leak tomorrow? You can't buy a new one, so you might have to replace it with a homemade nest of steel fin-tube radiation. That's when you have to pay close attention to those dimensions.

Q: Does it matter which way the air approaches the radiator?

A: The old-timers always tried to get the cold air to come in from the bottom of the radiator.

Set up this way, they could take advantage of natural convection currents. If they couldn't do it this way, they took their next best option and brought the fresh air in from the side opposite the warm air outlet.

Q: Are the registers in the rooms the same size as the flues which feed them?

A: No, the registers are usually about 25% greater in area than the flues.

Q: Did they use fans to move the air around the house?

A: No, this system worked purely on convection currents. Hot air, being lighter than cold air, naturally rises up into the building.

Q: Does the hot air move more quickly to the top floors than it does to the lower floors?

A: It sure does, and that's because of the chimney effect created by the taller, second- and third-floor flues.

Q: How much faster does the heated air move to the upper floors?

A: Typical air velocities are 1-1/2 feet per second to the first floor, 2-1/2 feet per second to the second floor, and 5 feet per second to the third. As you can see, the air speeds up quite a bit as it moves higher.

Q: So could the old-timer feed more than one floor with a single flue?

A: No, because of these differences in velocity each flue served only one floor.

Q: Did they size the flues going to the upper floors differently from the way they sized the flues leading to the lower floors?

A: Well, they had to size for Btu load, of course, but given that two rooms (one on the first floor, the other on the second or third) were equal in size, the flue going to the upper floor could be about 25% smaller than the one serving the lower floor because of the greater air velocity.

Q: Were the registers on the upper floors smaller than the ones on the lower floors as well?

A: Yes, they were. And this is where things can get tricky if all you're looking at is the register.

Q: Can I equate modern register or duct sizing with this type of heating?

A: Not if you want to stay out of trouble. The two are very different.

Q: Did they use circulator to move the water from the boiler to the indirect radiators?

A: No, they didn't have circulators in those days. They used the same piping techniques we looked at before when we talked about gravity hot-water heating. The difference here was that the runs to and from the radiators wasn't as long as it was in a direct, gravity hot-water system. That made the piping less complicated to size and install.

Q: How did the old-timers figure the heat loss for these old buildings?

A: Most used the "Mills Rule."

Q: What's that?

A: It was a rule-of-thumb method developed by John Mills, a famous 19th Century heating engineer. Simply put, the Mills Rule allowed:

- One square foot of radiation for each 2 square feet of glass in the building

- One square foot of radiation for each 20 square feet of exposed wall, ceiling or floor in the building, and

- One square foot of radiation for each 200 cubic feet of room volume.

The old-timer would total these three things and that would be the heat loss for the building.

Q: Can you give me an example of the Mills Rule in action?

A: Sure! Let's take a room measuring 10' X 20'. Two walls are exposed to the outside and the ceiling is 10'. The room is on the first floor, under a heated second floor, but over an unheated basement. In one of the walls there's a window that measures 5' X 4' and in the other wall there's a window measuring 8' X 5'

First, let's figure the glass. The 5' X 4' window equals 20 square feet, and the 8' X 5' window gives us another 40 square feet for a total of 60 square feet of glass. Divide that by 2 to convert it to square feet of radiation and you'll come up with 30 sq. ft. of radiation required to overcome the heat loss through the glass. If the room had a door, you'd treat it the same way.

Now for the "walls." There are three exposed surfaces in this room - the two walls and the floor. We'll treat them all as "walls." We don't consider the ceiling because it's under a heated space so there will be no heat loss there. The same goes for the other two walls; they're also next to heated spaces.

Let's convert the two walls and the floor to square feet:

10' X 20' = 200 sq. ft. (first wall)

10' X 10' = 100 sq. ft. (second wall)

10' X 20' = 200 sq. ft. (the floor)

We have a total of 500 square feet of surface exposed to the cold outdoors. Divide that by 20 to get square feet of radiation and you'll come up with 25.

Next, we measure the volume of the room by multiplying the length by the width by the height: 20' X 10' X 10' = 2,000 cubic feet. Divide that by 200 to get square feet of radiation. The answer is 10.

Now you add the glass (30 square feet of radiation) to the walls (25 square feet of radiation) to the volume (10 square feet of radiation). The total is 65 square feet of radiation.

Q: Was the Mills Rule based on steam or hot water?

A: It was based on steam. Radiation was only rated for steam when John Mills was alive. To figure their hot-water radiators, they'd add 60% to the Mills numbers.

Q: So for the example problem, how many square feet of hot water radiation would they have used?

A: They would have taken the 65 square feet they came up with based on the Mills Rule and multiplied it by 1.6. That would give them 104 square feet of hot water radiation.

Q: What is that equal to in Btu/hr?

A: Each square foot of hot water radiation is equal to 150 Btu/hr. This is based on an average water temperature of 170 degrees. So according to the Mills Rule, the heat requirement for the example would be: 104 X 150 = 15,600 Btu/hr.

Q: Will this method of calculating heat loss work today?

A: Not with our modern construction methods. If you used the Mills Rule today, you'd wind up with a system that's much larger than it has to be on the coldest day of the year. Your price would be way out of line if you were competing against someone who did an accurate heat-loss calculation.

Q: If you calculated the heat loss of this same room using modern computer software what would you come up with?

A: About 40% of what the Mills Rule gave us.

Q: How about if I'm figuring a heat loss on an old house? Would it be safe to use the Mills Rule then?

A: Only if the house has all the original equipment. In other words, no replacement windows or doors, no weather-stripping, no insulation. When I figured the heat loss on the sample room using the heat-loss software, I assumed someone had installed replacement windows and insulation. Makes a big difference, doesn't it?

Q: Considering the old-timers were using fresh air to heat the building, did they have to increase the load even further than what the Mills Rule called for?

A: They sure did, and by an impressive amount! Typically, for an indirect hot-water system they'd use the Mills Rule to figure the heat loss of the house as though it were going to be heated with direct steam radiators. Then, as I said, they'd add 60% to their radiation load to make it work with hot water, which is cooler than steam. And then, they'd add a whopping 75% to what they already had to compensate for the cold fresh air that would be coming in through the basement duct.

Q: So in the case of the example room, what would happen?

A: The old-timers would have taken the 15,600 Btu/hr load and multiplied it by 1.75. Then they would have installed indirect radiation capable of dumping 27,300 Btu/h into the room.

Q: Is that why those indirect radiators are so humongous.

A: Yep.

Q: Suppose I'm replacing a boiler and I find out the home owner is no longer using the 100% fresh air feature of the indirect system, do I still have to add that 75% extra to my load calculation?

A: No. If you did, your boiler would be ridiculously oversized.

Q: Is it practical to keep an indirect system operating nowadays with 100% fresh make-up air?

A: When you consider the cost of fuel, this system really isn't practical anymore. We've learned that "vitiated air," the scourge of Victorian America, is not the only thing that can make you ill. Many home owners, in an attempt to save money, have chosen to abandon the ventilation side of the indirect system.

Q: How do you abandon the ventilation side of the system?

A: Usually, all you have to do is seal the cold air inlet duct and open the radiator access door. That will allow the air in the basement to move through the heaters and up into the rooms.

Q: Does this always work?

A: I've seen mixed results. How well it works depends largely on whether or not the air in the rooms can work its way back down to the basement. Also, if the basement isn't squeaky clean, the smells that waft upstairs will have the home owners holding their noses. It's a guaranteed call-back for you.

Q: Suppose the air in the rooms air can't work its way back down to the basement?

A: You're going to get less heated air from the registers than you did when you were using the outside air duct, of course. Remember, air can't come out of the registers in the rooms unless air can get in at the heaters, so you may have to cut return air ducts into the first floor rooms to get good circulation.

Q: Is this practical?

A: Not always.

Q: Which brings up another thought. When the outside-air duct was open, how could all that fresh air enter the house? Didn't an equal amount of air have to leave?

A: Good question. As the warmed, fresh air came up through the registers, the air that was already in the rooms had to leave, and it did. It went out through the many cracks in the building, around the windows and doors, the places where floor and walls came together, the fireplaces. The house acted like a chimney.

Q: So if I were to weatherize and tighten up an old house that has this type of indirect heating system I'm liable to mess up the heating system?

A: That's right. If you stop the air from leaving, less air will enter and the heating capacity of the radiators will drop off considerably.

Q: But will I still be able to heat the house?

A: It depends. Most of the time, the old-timers were so generous with their radiation sizing that you'll probably find the house heats well even with the lesser movement of air through the indirect radiators.

Q: So I won't have a problem?

A: Hey, I never said that! I remember visiting a house with indirect hot-water heat once. The home owner wanted to save fuel so he sealed all the cracks in the house and closed and caulked the outside air duct. Not too much air got in or out of his house. And because it couldn't, he was freezing. And yet his fuel bills were higher than ever because no warm air could make it out of the basement ductwork and up to his thermostat. The burner ran all day, and yet the guy was freezing. Imagine that.

Leave a comment

Related Posts

In this all-technical three-hour seminar, Dan Holohan will give you a Liberal Arts education in those Classic Hydronics systems. He’ll have you seeing inside the pipes as...

We always have turkey for Thanksgiving. I mean who doesn’t? My job wasn’t to cook it, though; it was to eat it.