This all-technical, three-hour seminar will make you familiar with the many types of old steam heating systems and what goes wrong with them. Dan Holohan’s easy-to-follow...

Steam Boiler Care During The Pandemic

During this pandemic, most brewers are shut down, and no one knows when we as a country will restart. During this time, it is easy to forget about the boiler, and that could be costly in the future.

Corrosion Concerns

When your steam boiler is sitting idle, the water will reabsorb the oxygen and start corroding from the inside out. At 212 Degrees F, the oxygen content in the water is about 0 parts per million or PPM. As the water cools, oxygen molecules reunite with the water. At 150 Degrees F, the oxygen is at 4.3 parts per million. When the water reaches room temperature or about 70 Degrees F, the oxygen percentage doubles to 8.6 PPM and starts to devour the boiler. Oxygen corrosion is twice as corrosive at 86 Degrees F than at 122 Degrees F.

What can you do to avoid this corrosive smorgasbord? You could keep your boiler hot, and this will keep the oxygen molecules at bay somewhat, but this could be expensive, especially since you have no customers coming in the door. While you don't know when you will open, I would suggest injecting some extra water treatment chemicals into the boiler. This will add more oxygen scavengers to battle the oxygen molecules. You could also fill your boiler with water, and this will push the air out of the boiler. Check with your water treatment expert for how much treatment should be injected. I would suggest leaving a note on the boiler reminding you it is flooded. After the stay at home order is lifted, and you are ready to brew, remember to drain the boiler. You will also have to test the treatment levels as they may be high.

This may be an opportune time to perform the preventive maintenance on the boiler and steam system. The following is a list of things you can do for little or no cost:

Look Around

Walk around the boiler room and look for water leaks or rusted pipes/fittings. If you notice water dripping or leaking, the leaks should be repaired. If your boiler does not have a power burner (A burner with a blower), you could look at the burners to see if they are dirty or have rust on top. If so, they could be cleaned. If you feel uncomfortable doing that, the boiler service companies are still working because we are considered life-sustaining businesses. While looking at the burners, look at the condition of the refractory. The refractory is the white or ivory-colored materials that look like insulation. These are installed to protect the metal surfaces from flame impingement. If you see cracks or missing pieces, the boiler should not be fired until the refractory is repaired or replaced. This may not be a job for the brewmaster as refractory becomes crystalline silica, a known carcinogen, when exposed to flame.

Check the combustion air openings to see if they are free and clear. Remove any debris which may be blocking the air from entering the boiler room. We commonly find grass clippings, plastic shopping bags, or random pieces of paper blocking the openings.

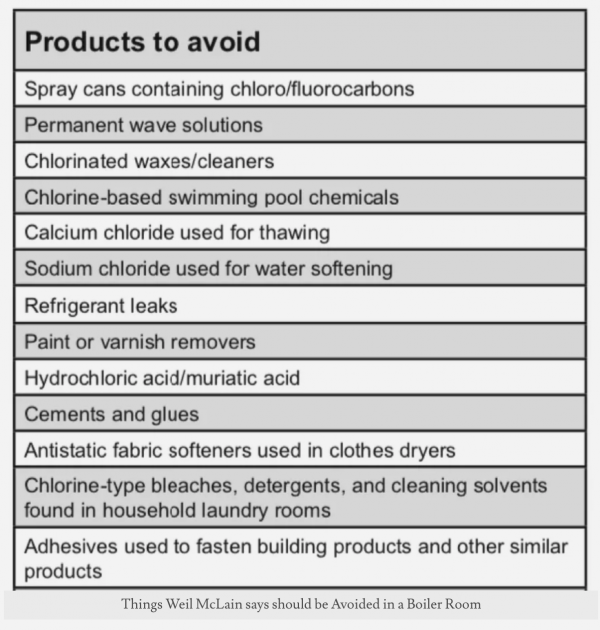

Look around to see if anything is stored in the boiler room, which should not be there. This could be things like paint or varnish remover, chlorine type bleaches or cleaners, spray cans, calcium chloride for snowmelt, or sodium chloride for a water softener. If they are, do your boiler a favor and remove them from the boiler room as they could interact with the flame and damage the boiler. Verify there is enough room to walk around the boiler. Most boilers require about 30 inches around it for proper service and combustion.

Verify the boiler feed tank is not leaking. This is the tank with a pump or two which feeds water to the boiler.

The flue pipe should be viewed to be sure the joints are intact, and there is no evidence of rust or holes. This pipe sends the dangerous flue gases from the boiler to the chimney and outside.

Lastly, look at the boiler jacket for discoloration or black streaks. A discolored boiler jacket could indicate the flue gases may be misdirected and overheating the jacket. The boiler should not be fired until the cause of the discoloration is discovered. Black streaks on the bottom of the jacket or around where the burner is mounted to the boiler could indicate soot is forming as a result of incomplete combustion. The boiler should not be operated until the source of the soot is discovered. Soot is hazardous and should be handled by a professional.

Sniff Around

Your nose is an excellent leak detector for natural gas. Gas, in its natural state, is odorless. Mercaptan is added to gas to give it that distinctive odor. If you smell gas, the leak should be found. Leak testing can be done by adding dishwasher detergent to water and painting the pipe joints with the mixture and looking for bubbles. Natural gas leaks will show bubbles at the point of leaking. Do not paint any electrical components or wires with the water and soap mixture. If some is spilled on the wires, it should be immediately dried with a rag. Remember the gas will only be up to the first electric valve when the boiler is off. When done leak testing, wipe any spilled leak testing solution as it is slippery, and you could be suddenly on your back.

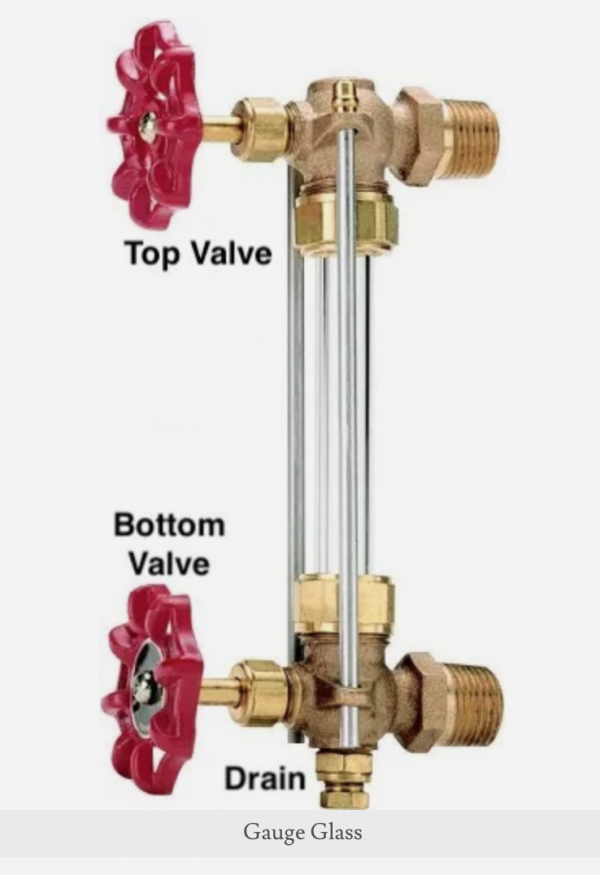

Is the gauge glass dirty? The gauge glass is the vertical tube on the front of the boiler that shows the water level inside the boiler. You should be able to see the water level inside the gauge glass unless you have flooded your boiler, as I suggested above. If the gauge glass is dirty, it can be removed and manually cleaned. It's a bit tricky and may not be something you would want to attempt yourself. Another way of cleaning the gauge glass, which does not require disassembly, is to use steam from your boiler. Close the steam valve on the boiler outlet, which goes to the steam piping. Start the boiler, and when the boiler reaches about 2 Psig, shut off the burner. Place plastic below the gauge glass to protect any electrical components.

Wear gloves and safety glasses because it will be hot. You can get third-degree burns in less than a second with steam. Close the valves directly above and below the vertical gauge glass tube. Open the drain at the bottom of the gauge glass. It looks like a small screw with sides where a crescent wrench can be placed. Loosen the screw until water starts to seep. When the water stops, open the top valve above the gauge glass. This will inject steam into the tube and should scrub the inside of the tube, cleaning it. The steam and hot water will shoot out the drain, so be sure you are not in the path of the hot mixture. After a few seconds, close the top valve, then the drain valve. Open the bottom valve directly below the vertical glass tube and reopen the top valve. There, you have steam cleaned the gauge glass.

Would you like to learn more from Ray Wohlfarth? Check out his seminars, books, and blog about brewing with steam.

Leave a comment

Related Posts

We always have turkey for Thanksgiving. I mean who doesn’t? My job wasn’t to cook it, though; it was to eat it.

I had written a story for Plumbing & Mechanical a while back about a fella in Canada who sent me this email: "Our problem is that five out of hundreds of univentilator co...